Autonomous Mobile Robots (AMRs) bring a new level of flexibility to modern factories by automating material transport, logistics, and workflows. Unlike traditional Automated Guided Vehicles (AGVs) that follow fixed paths, AMRs use AI-driven navigation and sensor fusion to adapt in real time, making them perfect for dynamic industrial environments.

Key Hardware Requirements for AMRs

Computing Essentials for Smart Factory Autonomous Robots

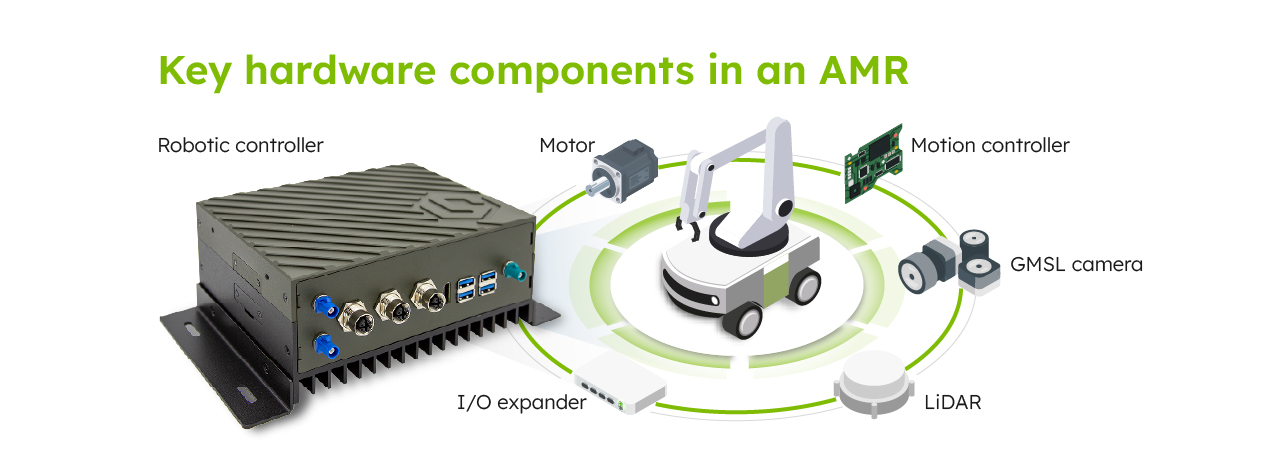

Robotics and autonomous systems rely on a powerful hardware backbone for seamless industrial automation. Key hardware requirements include:

1. High-Performance Computing

Robotic controllers require real-time data processing to analyze their environment and make split-second decisions. ACROSSER embedded computers powered by NVIDIA Jetson Orin™ deliver this high-performance AI and future-proof processing power for evolving industrial needs.

2. Comprehensive I/O Connectivity

Industrial AMR computing solutions must support diverse sensor inputs, such as LiDAR, cameras, and radar. Rich I/O interfaces ensure scalability, allowing seamless integration of additional sensors and peripherals for expanded functionality.

3. Reliable High-Speed Networking

AMR automation requires fast and stable wireless communication for seamless fleet coordination and cloud integration. Embedded computers should offer 5G, LTE, and Wi-Fi modules along with SIM card compatibility to facilitate real-time data exchange, autonomous coordination, and efficient task execution.

Key Applications

Factory & Warehouse Automation

Production Line Optimization

Safety First

The Evolution of Autonomous Robotic Systems in Manufacturing

Future Forward AMR Robotics

From logistics to production automation, AMR automation is evolving beyond moving materials around. They’re now integral to manufacturing processes, contributing to assembly line automation and quality control for increased efficiency.

Manufacturing Uptime, Optimized

As adoption grows, get more rapid customization, predictive maintenance, and real-time support with minimal downtime and maximum efficiency.

Workforce Automation

Drive operational efficiency by automating manual tasks and addressing rising labor costs and workforce shortages.

Scalable Deployment

Expand AMR applications into new sectors with scalable, flexible solutions tailored for diverse manufacturing needs.

Supercharge AMR Automation

Integrate AI, IoT, and edge computing for real-time decision-making, autonomous navigation, and cloud-based analytics, enhancing adaptability and performance.

Standardization vs. Customization

Design AMRs with modular designs to balance customization for niche applications with standardized models for mass adoption.

The ACROSSER AMR Advantage

Doing more every day just became so much more doable. Our industrial edge computers powered by NVIDIA Jetson Orin™ NX deliver AI-enhanced navigation, real-time processing, and blazing-fast connectivity.

Unleash the Power of ACROSSER Robotic Controller

Discover how our edge computers enhance AMR automation.

| Ask an Expert |